Types of optical mirrors

Optical Flat Mirrors

Custom optical mirrors optimized for specific solutions. Get in touch with the sales team for more information about our stock of flat mirrors.

.

Ultrafast Mirrors

E-Max is able to attain the highest pulse Energy damage threshold. B-Max optical coatings can deliver the Broadest possible bandwidth.

Nd:YAG Laser Mirrors

Broadband Mirrors

Laser Line Mirrors

IR Mirrors

Concave Mirrors

Off-Axis Mirrors

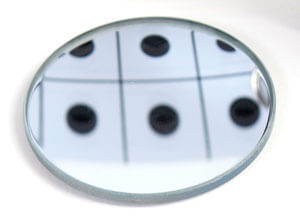

Custom Optical Mirrors

Our technical team will review your optical drawing and provide pricing. Typically we offer:- Size: 3 to 400 mm

- Surface roughness: 3Ǻ with the ability to provide below 1Ǻ if requested

- Reflectance: up to 99.5%

- Standard tolerances include +0/-0.005″ for diameter, length or width and ± 0.005″ for thickness

- Surface flatness: we routinely provide 1/10λ Peak to Valley or Irregularity for radius at 632.8nm, able to achieve 1/40λ

- Parallelism: 1 minute with can go below 5 seconds on plano/plano parts as needed

- Wavelengths: 193-3000 nm

- Surface quality:

- AOI: 0-60 deg

Laser Mirrors TechnologyThe laser optics technology employed to fabricate these performance optics has evolved from producing them for some of the world’s most demanding laser systems. ARO supplies for the largest system at the Lawrence Livermore National Laboratory National Ignition Facility for state-of-the-art microlithography tools. From substrate preparation to product packaging, the same expertise and care goes into making these cutting-edge stock and custom-built items available for you. |

Stock and custom precision optics manufacturingMirror optical productsOptical mirrors include a variety of stock excimer, hot and cold mirrors, specialty mirrors, ultrafast laser mirrors, parabolic, and solid-state for use in ArF, KrF, Ti:Sapphire, and Nd:Yag laser systems. Our stock range of laser mirrors covers the most commonly required specifications in terms of wavelength, size, reflectivity, and angle of incidence. These represent just a small sampling of our production capabilities. The bulk of our business is devoted to the manufacturing of optics, mirrors, and lenses built to customer-supplied specifications. We can readily produce fully customized mirrors in virtually every aspect, including size, shape, substrate material, front surface optical mirrors specifications, and performance characteristics. We make coated mirrors, dichroic mirrors, surface mirrors, reflectivity mirrors, broadband dielectric mirrors, a surface mirror, and more. Please contact our technical sales department to discuss your requirements. |

Optical Mirror Manufacturer

Industrial Applications

We are engineering small, medium, and large mirrors for a variety of industries. They are optimized to reflect light to be used in laser mirror systems. Among the possible applications are beam steering, imaging, and illumination. For over 30 years, ARO has been developing only the highest quality of the optical mirror glass. We follow advanced industry practices to provide customers with the best possible product. Among the industries we can distinguish astronomy, metrology, semiconductor, and energy system. If you have any questions about the industrial optical mirrors advanced design, you can always consult with our specialists.

Optical mirror coating

With us, you can be sure that we only use the most suitable materials for your specific custom optical mirror, lenses manufacturer project. We use different materials and always strive to match the specifications to you need. Our engineers have been working with the creation of dielectric mirror coating, lenses, or other optical components for more than twenty years. Our experienced technicians know all the nuances surrounding functionality and the creation of a variety of laser mirrors, regardless of their type, shape, and material. So if you are looking for custom optical systems, or metal coated optical mirrors for sale, we can help!

Choosing the right option can be critical depending on the application, as it ensures the highest reflectivity for the desired wavelength range. We work with aluminum, reflective coatings, glass mirror coating, and dielectric coatings. The choice of the shape and material from which parabolic mirror optics, convex mirrors optics, fused silica, and others are made can be just as important. Regardless of the specifications, you can be sure that the final product will always achieve the required standards.