Our infrared optics cover a broad range of the most commonly required specifications in terms of wavelength, size, reflectivity, and angle of incidence. ARO’s Emax mirrors for Ti:Sapphire systems are known for providing excellent laser damage threshold performance. Our TFP polarizing beam splitters split light into two beams by transmitting p-pol and reflecting s-pol light. If you don’t find what you are looking for in our catalog, we can also readily produce infrared optics customized in virtually every aspect, including size, shape, substrate material, surface specifications, and performance characteristics. ARO can select from E-beam, magnetron sputtering, IBS, and ion-assisted deposition coating techniques based on your requirements. Contact (hyperlink to quote request page) our technical sales department to discuss our stock or custom infrared optic options.

Infrared Mirrors

High bandwidth B-Max coatings at 800 nm | |||||

|---|---|---|---|---|---|

| Wavelength (nm) |

Diameter (mm) |

Thickness (mm) |

Angle of Incidence |

Reflectivity* (%) |

Part Number |

| 800 (B-Max) | 25.4 | 9.525 | 0° | 99.5 | MR6020 |

| 800 (B-Max) | 25.4 | 9.525 | 45° | 99.5 | MR6040 |

| 800 (B-Max) | 50.8 | 9.525 | 0° | 99.5 | MR6060 |

| 800 (B-Max) | 50.8 | 9.525 | 45° | 99.5 | MR6080 |

1053nm Mirrors for Nd:Yad Laser Systems | |||||

|---|---|---|---|---|---|

| Wavelength (nm) |

Diameter (mm) |

Thickness (mm) |

Angle of Incidence |

Reflectivity* (%) |

Part Number |

| 1053 | 25.4 | 9.525 | 0° | 99.5 | MR7720 |

| 1053 | 25.4 | 9.525 | 45° | 99.5 | MR7740 |

| 1053 | 50.8 | 9.525 | 0° | 99.5 | MR7760 |

| 1053 | 50.8 | 9.525 | 45° | 99.5 | MR7780 |

high laser damage E-Max Coatings at 800 nm | |||||

|---|---|---|---|---|---|

| Wavelength (nm) |

Diameter (mm) |

Thickness (mm) |

Angle of Incidence |

Reflectivity* (%) |

Part Number |

| 800 (E-Max) | 25.4 | 9.525 | 0° | 99.5 | MR6220 |

| 800 (E-Max) | 25.4 | 9.525 | 45° | 99.5 | MR6240 |

| 800 (E-Max) | 50.8 | 9.525 | 0° | 99.5 | MR6260 |

| 800 (E-Max) | 50.8 | 9.525 | 45° | 99.5 | MR6280 |

1064nm Mirrors for Nd:Yag Laser Systems | |||||

|---|---|---|---|---|---|

| Wavelength (nm) |

Diameter (mm) |

Thickness (mm) |

Angle of Incidence |

Reflectivity* (%) |

Part Number |

| 1064 | 25.4 | 9.525 | 0° | 99.5 | MR8020 |

| 1064 | 25.4 | 9.525 | 45° | 99.5 | MR8040 |

| 1064 | 50.8 | 9.525 | 0° | 99.5 | MR8060 |

| 1064 | 50.8 | 9.525 | 45° | 99.5 | MR8080 |

Infrared Polarizer

Plate polarizer at 1053 nm for Nd:Yag lasers | |||||

|---|---|---|---|---|---|

| Wavelength (nm) |

Dimensions (mm) |

Thickness (mm) |

Angle of Incidence |

Extinction Ratio |

Part Number |

| 1053 | 28.6 x 14.3 | 3.2 | 56°±3° | 200:1 | PL7720 |

Plate polarizer at 1064 nm for Nd:Yag lasers | |||||

|---|---|---|---|---|---|

| Wavelength (nm) |

Dimensions (mm) |

Thickness (mm) |

Angle of Incidence |

Extinction Ratio |

Part Number |

| 1064 | 28.6 x 14.3 | 3.2 | 56°±3° | 200:1 | PL8020 |

TFP Polarizers

Tp Bias plate polarizers at 800 nm for Ti:Sapphire lasers | |||||

|---|---|---|---|---|---|

| Wavelength (nm) |

Dimensions (mm) |

Thickness (mm) |

Angle of Incidence |

Tp (%) / Rs (%) |

Part Number |

| 740 – 860 | 28.6 x 14.3 | 3.2 | 70°±3° | 98/75 | PL6020 |

Rs Bias plate polarizer at 800nm for Ti:Sapphire lasers | |||||

|---|---|---|---|---|---|

| Wavelength (nm) |

Dimensions (mm) |

Thickness (mm) |

Angle of Incidence |

Tp (%) / Rs (%) |

Part Number |

| 700 – 900 | 28.6 x 14.3 | 3.2 | 70°±3° | 75/95 | PL6040 |

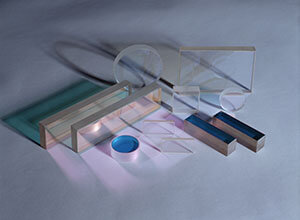

Custom Infrared Optics

Calcium Fluoride Optics

Fused Silica Optics

Magnesium Fluoride Optics

Other IR Materials

Custom Infrared Coatings

Our technical team will review your IR optical drawing or custom specifications and provide a quote. Typically we offer:

Infrared Optic CoatingsARO has particular experience with designing optical coatings for near-IR applications. We offer a variety of stock and custom NIR optics. Our mirrors and polarizers for Nd:Yag, Yb:Yag, and Ti:Sapphire laser systems are trusted by the world’s industry leading laboratories. Our high quality standards mean our parts will perform longer, saving you time and money. | |||

Infrared Reflective CoatingFor the past 30 years, ARO has been optimizing NIR coatings for some of the world’s most prestigious laboratories. Our IR optics are trusted by Lawrence Livermore National Laboratories, SLAC, and MIT to withstand their cutting-edge applications. We have optimized the quality and performance of our IR optical coatings so that your parts last longer and perform better. Our experienced R&D engineers take pride in the damage threshold, bandwidth, and performance specifications our coatings achieve. | |||