Optical Coating Process

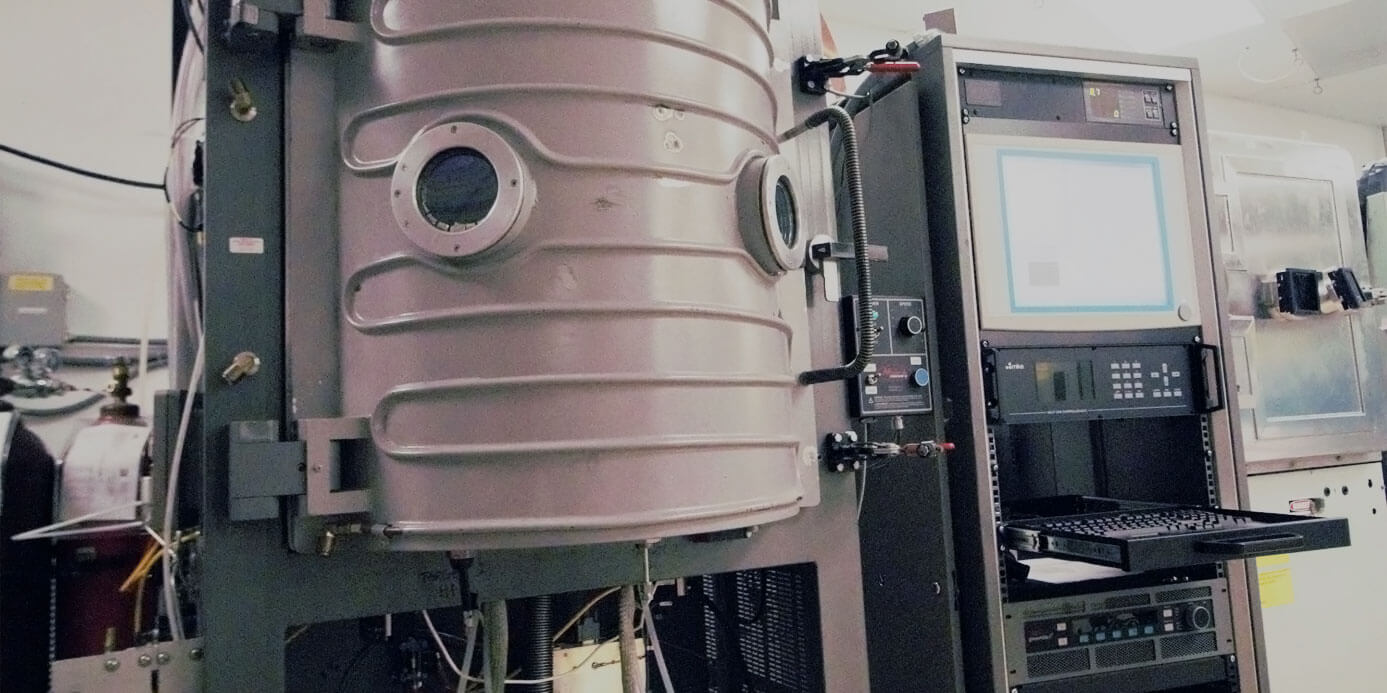

ARO offers a complete catalog of coatings – anti-reflective coating optics, broadband AR, short and long wavepass filters, high reflectors, optical beam splitters and polarizers. We have a variety of coating technologies available to satisfy the spectral, mechanical, laser damage, and environmental conditions of customer required coatings. Our chambers range in size from 28” to 54”. We clean and inspect our optics in a class 10,000 clean room and use other techniques to produce absolute pristine surfaces. ARO uses FilmStar design and characterization software to design customized coatings.

We have a strong reputation for excellent performance in the UV-Excimer wavelengths, starting at 193 nm. ARO uses evaporative E-beam technology for many of or our thin film coatings because this method is typically faster and less expensive than alternative methods on the market. For thin film coatings at lower wavelengths, using E-beam technology allows ARO to produce optics with some of the highest laser damage certifications and longest lifetimes in the industry.