Recent Posts

- Angle of Incidence

- Diameter Tolerances

- Extinction Ratio

- Reflectivity

- Surface Quality

- Material

- Surface Flatness

- Infrared Optics

- Dimensional Tolerances

Texture

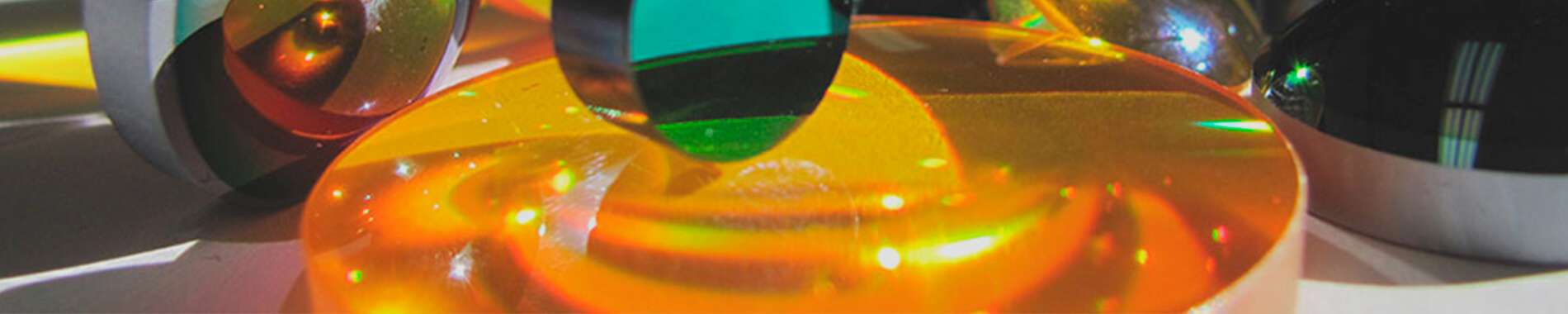

Surface roughness is the texture of an optical surface on a microscopic scale, as opposed to flatness, power and irregularity which all relate to large scale (macroscopic) surface shape. This which can be defined a number of different ways (arithmetic average, root mean square, etc.) is usually given in units of length directly, such as angstroms. The primary method by which we determine it is through the use of a Phase Shift white light interferometer.

surface roughness measuring

IT is generally only specified for certain types of demanding laser applications, and doesn’t significantly impact the performance of most optical components. To service low surface roughness applications, ARO has developed a number of proprietary polishing techniques. These involve specialized equipment, and also require paying close attention to factors such as the temperature, pH balance and contaminant level of the polishing slurry.

Contact Alpine Research Optics for any information regarding laser precision optics for sale or the coating technology.