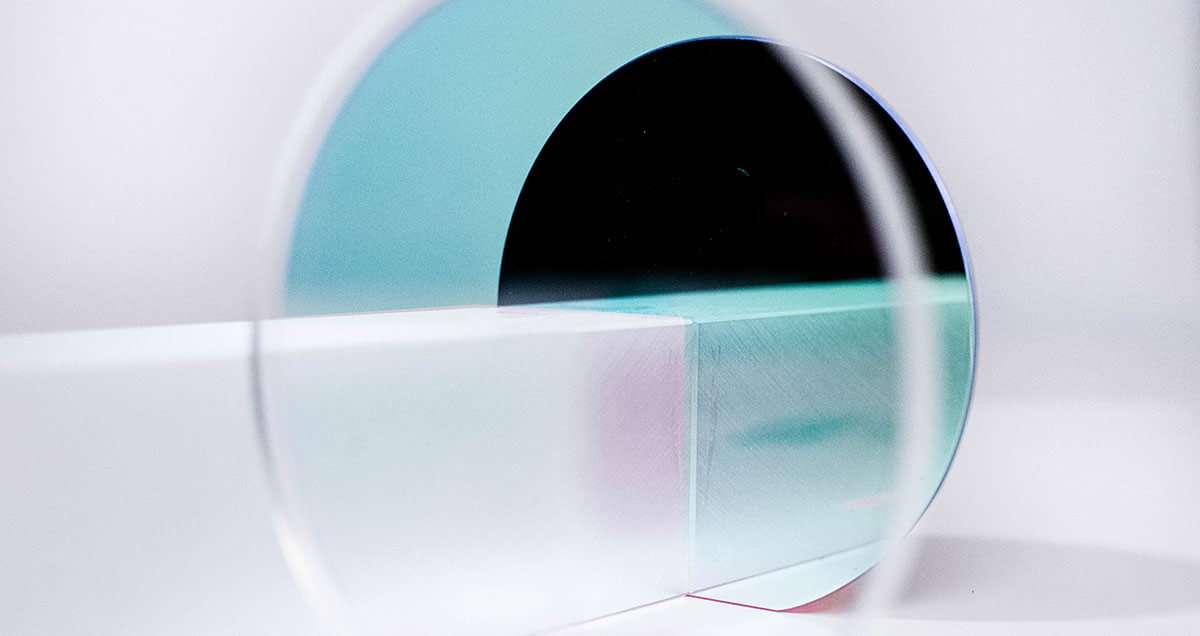

Ti:Sapphire MirrorsOur ultrafast mirrors are designed to deliver superior performance for demanding beam steering tasks in Ti:Sapphire laser applications. Close cooperation between our design staff and leading ultrafast optics researchers has enabled our optical fabrication technology develop to precision optics that deliver an optimum combination of high reflectivity, broad spectral bandwidth, excellent laser damage resistance, and minimal group delay dispersion. | |||

ARO supplies two standard series of ultrafast laser mirrors. Our B-Max coatings are optimized to deliver the Broadest possible bandwidth, while our E-Max reflectors are specifically optimized to attain the highest pulse Energy damage threshold. In addition to these stock components, we can readily produce precision optics customized in virtually every aspect, including size, shape, substrate material, surface specifications and performance characteristics. Please contact our technical sales department to discuss your custom optics requirements.

High bandwidth B-Max coatings at 800 nm | |||||

|---|---|---|---|---|---|

| Wavelength (nm) |

Diameter (mm) |

Thickness (mm) |

Angle of Incidence |

Reflectivity (%) |

Part Number |

| 25.4 | 9.525 | 0° | 99.5 | MR6020 | |

| 25.4 | 9.525 | 45° | 99.5 | MR6040 | |

| 50.8 | 9.525 | 0° | 99.5 | MR6060 | |

| 50.8 | 9.525 | 45° | 99.5 | MR6080 | |

High laser damage E-Max Coatings at 800 nm | |||||

|---|---|---|---|---|---|

| Wavelength (nm) |

Diameter (mm) |

Thickness (mm) |

Angle of Incidence |

Reflectivity (%) |

Part Number |

| 25.4 | 9.525 | 0° | 99.5 | MR6220 | |

| 25.4 | 9.525 | 45° | 99.5 | MR6240 | |

| 50.8 | 9.525 | 0° | 99.5 | MR6260 | |

| 50.8 | 9.525 | 45° | 99.5 | MR6280 | |

Optical Mirrors Specifications

- Clear Aperture: 85%

- Wedge:<5 arc minutes

- Flatness: λ/10 at 633 nm

- Surface Quality: 10-5

- Material: Fused Silica

- Thickness Tolerance: ±0.25 mm

- Chamfer: 0.50 mm at 45°

- Diameter Tolerance: +0.00, -0.13 mm

- Rear Surface: Commercial Polish

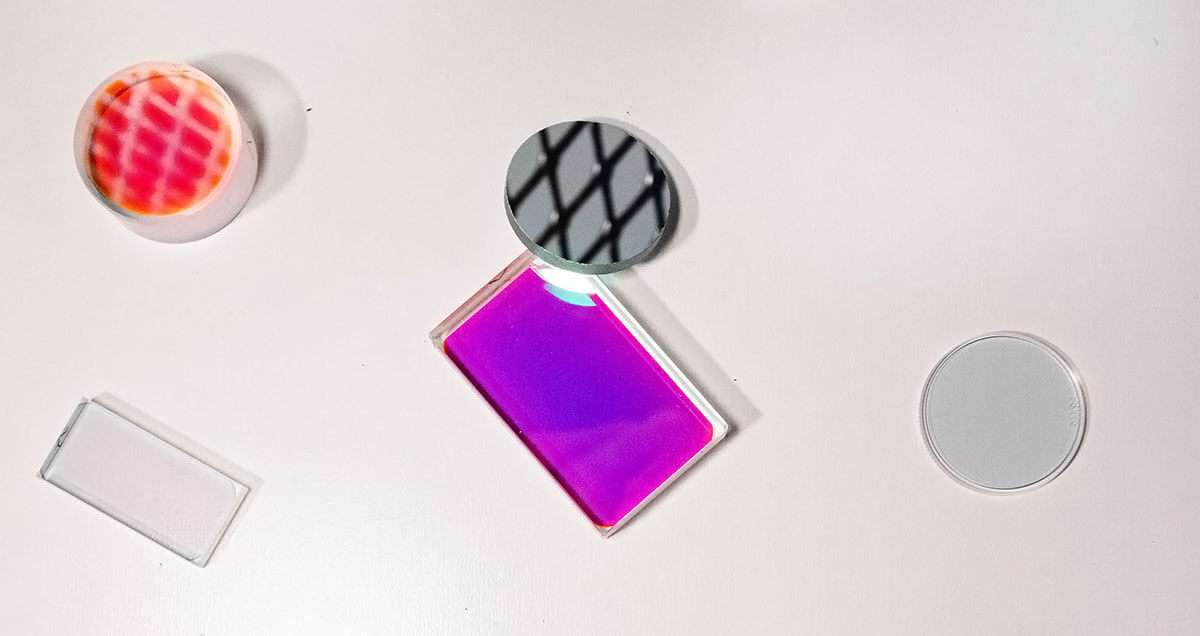

Spectral Shaping FilterOur unique shaping filter provides a simple route to shorter pulses (as short as 10 femtoseconds) from Titanium: sapphire ultrafast amplifiers. This new intra-cavity optic is a dielectric coated filter with a spectral transmission curve designed to precisely compensate for the wavelength dependence of the Titanium: sapphire gain curve. Since the center wavelengths near 800 nm are preferentially amplified, the amplified pulse is effectively narrowed in wavelength (narrowing results in pulse lengthening in transform-limited laser pulses). |

Our spectral shaper is an intra-cavity coated optic that has a transmission curve that is the mirror image of the Ti:S gain curve. With this optic inserted in an amplifier, the spectral curve for single-pass cavity gain is now a flat line rather than a gaussian. Both the center wavelength and the magnitude of the single-pass gain correction can be easily adjusted with the Spectral Shaping Filter. Specifically, varying the angle of incidence at which the optic is mounted causes a shift in the center wavelength.

This enables the filter performance to be matched to the skewed gain curve of chirped amplifiers. And, by rotating the filter angle relative to the beam polarization, its transmission maximum can be smoothly increased or decreased. This allows the same filter to be used in both a multi-pass or regenerative type amplifier. The particular performance specifications of the spectral filter can be optimized for OEM upon request. For more detailed information on how the it works, see the technical white paper entitled “The ARO Gain Flattener for Ultrafast Amplifiers.” Also, be sure to check out ultrafast polarizers section on our website.

Spectral Shaping Filter Catalog | |||||

|---|---|---|---|---|---|

| Wavelength (nm) |

Diameter (mm) |

Thickness (mm) |

Angle of Incidence |

Reflectivity (%) |

Part Number |

| 800 | 25.4 | 2.0 | 40° to 50° | 65 ± 8 | SF6040 |

| 800 | 50.8 | 4.0 | 40° to 50° | 65 ± 8 | SF6080 |

Spectral Filter

- Clear Aperture: 85%

- Wedge: <5 arc minutes

- Wavefront Distortion: < λ/10 at 633 nm over any 4 mm sub-aperture

- Surface Quality: 20-10

- Material: Fused Silica

- Thickness Tolerance: ±0.25 mm

- Chamfer: 0.50 mm at 45°

- Diameter Tolerance: +0.00, -0.13 mm

- Rear Surface: Commercial Polish