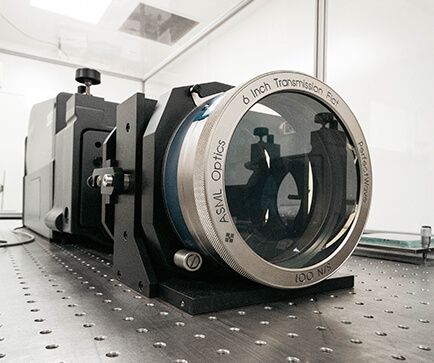

Optics Manufacturing Capabilities

With our in-house polishing equipment, coating chambers and state-of-the-art metrology, we guarantee parts are made to the highest quality standards from start to finish.

We fabricate precision optics to meet tight specifications in an array of shapes and sizes. We are knowledgeable and have experience with a wide variety of materials including optical glasses, fused silica, optical crystals (CaF2 & MfF2), and optical ceramics (Spinel & Zerodur).

We utilize E-beam, IBS, Magnetron Sputtering, and Ion Assisted Deposition coating technologies. Coating method is selected based on the customer’s spectral, mechanical, laser damage, pricing, and environmental specifications. We have a strong reputation for coating performance within 193-3000nm.

ARO uses state of the art metrology equipment to verify customer specifications. Metrology is used at each processing stage to ensure parts meet the highest quality requirements. Flatness is measured with a custom perfect wave reference flat with our Zygo interferometers.

Optics Capabilities

Our capability stems from our extensive equipment and tooling combined with the years of experience and technical knowledge of our engineers and operators. This combination makes for industry-leading coating, fabrication, and metrology capabilities.

ARO company has extensive equipment that allows us to produce the high-precision laser optics our industry demands. Our technicians use mills, grinders, spindle polishers, double-sided polishers, polishers, edgers, advanced cleaning equipment, spectrophotometers, and interferometers. We can choose from e-beam, magnetron sputtering, IAD, and IBS coating technology to provide you with the performance you need. While continually expanding and tightening the tolerances on our tooling, our engineers also focus on upgrading equipment and developing improvements to our existing processes. We attract, train, and develop a workforce that strives to expand our capability and operate our equipment with increased proficiency.